Cutting Tools

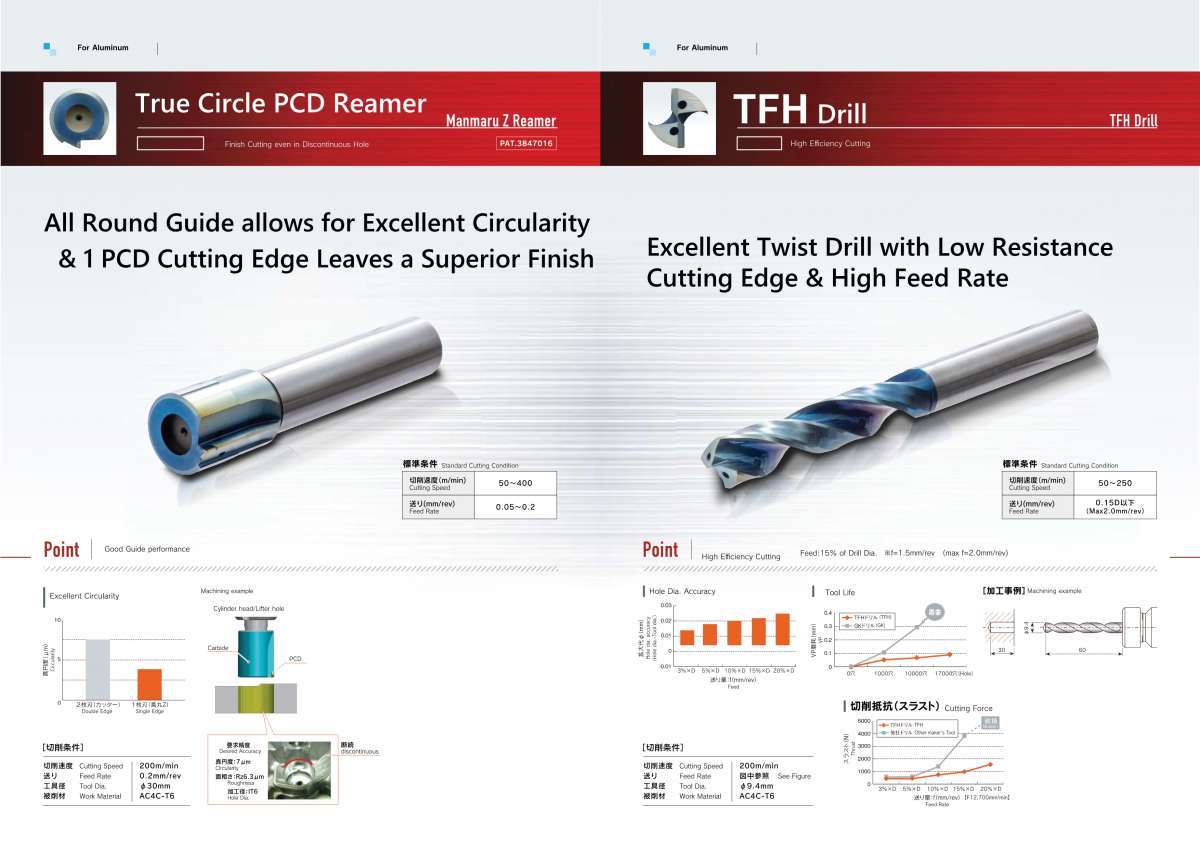

These are all complete custom tools and many of these can be configured to machine multiple geometries to eliminate tools in the turret. This can reduce your total operation time and increase your productivity. This can also give you more room when your turret is limited in size. We offer many different solutions for mainly aluminum and cast iron, but we do offer a few items for processing steel as well.